Products Details

Gold Dust Recovery Machine Manufacturers

Products Details

Gold Dust Recovery Machine Manufacturers

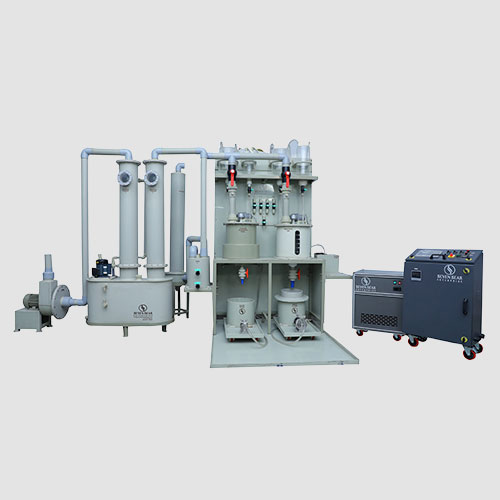

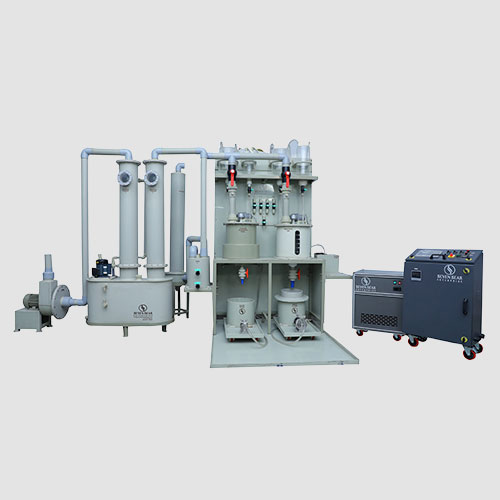

Seven Seas Enterprise as the Gold Dust Recovery Machine Manufacturers in Rajkot gets you only the best. Dry suction processes are suited for carpet dust and polishing waste, and wet filtration tanks for sludge or buffing residue handling oil or water content. What distinguishes our machine is its accurate material classification system, which separates dust according to density, weight, and particle size. Gold particles have a higher density compared to other material contents found in dust, such as cotton fibers, polishing wax, or plastic granules. The machine takes advantage of this density difference using calibrated air pressure, vibration frequency, and controlled flow channels pushing away lighter wastes while guiding heavier gold particles into the collecting section. The system that we have developed for businesses like you comes with the internal classifiers, dust collectors, cyclone separators, and micron filters for a complete and clean recovery system.

We are the most reliable provider of Gold Dust Recovery Machine Exporters based in India. The contact surfaces that come with are fashioned from stainless steel or anti-corrosion metals that can resist exposure to oil, moisture, and metal particles. Specialized airlock valves will keep particle leakage from occurring and ensure that gold trapped in the system remains within the retrieval path. Discharged material collected is released into closed tray or jars for easy opening for additional processing or melting purposes.

We understand that every client is different — with unique requirements, goals, and challenges. Whether you need a complete Gold Refining Plant, a Gold Dust Recovery Machine, or customized Bar Casting Equipment, we’re here to provide expert guidance and tailored solutions.

Contact Details Wide Range Of Products

Wide Range Of Products